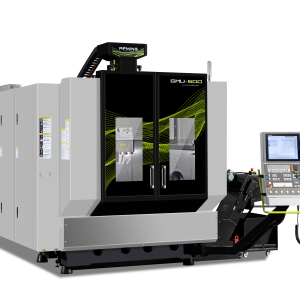

GMU-2518 5-axis Machining Center Introduction

GMU2518 is a universal 5-axis machining center with a high-rigidity and high-torque gear-driven turntable developed by AFMING, especially suitable for large-scale mold, auto parts, mechanical equipment, aircraft structural parts and other related industries complex multi-faceted and five-axis simultaneous processing.

| X/Y/Z stroke: | 1800/2500/800 | X/Y/Z rapid displacement speed: | 20/20/20m/min |

| A/C stroke: | ±120°/250° | Maximum cutting feed rate: | 10m/min |

| Distance between end face of spindle and workbench: | 500-1300mm | Dimension of machinetool: | 7950×5360×5600 |

| Dimension of workbench: | 1800×2500 mm | Maximum bearing capacity: | 8000 kg |

Five axis Universal Machining Center Advantages:

- The machine tool is a cross-rail moving beam gantry structure, which is especially suitable for multi-face and five-axis simultaneous processing of complex parts in related industries such as large molds, auto parts, industrial machinery, and aviation structural parts.

- The ram and the slide plate parts are fixed on the beam through the linear guide rail.

- The slide plate moves to the left along the X axis as the X axis, the ram moves up and down as the Z axis, and the beam moves back and forth as the Y axis.

- The offset double swing head is placed under the ram, and it is the C and A axes. It has a compact structure, super rigidity, and cozy operating comfort.

- Static torque of A axis drive: 1600 N.m

- Static torque of C axis drive: 2000 N.m

- Torque of A axis brake: 2500 N.m

- Torque of C axis brake: 3500 N.m

- Speed of spindle: 24000/HSK-A63

- Power of spindle (S1/S6-40%): 29/38 KW

- Torque of principle axis (S1/S6-40%): 69.4/86.8 N.m

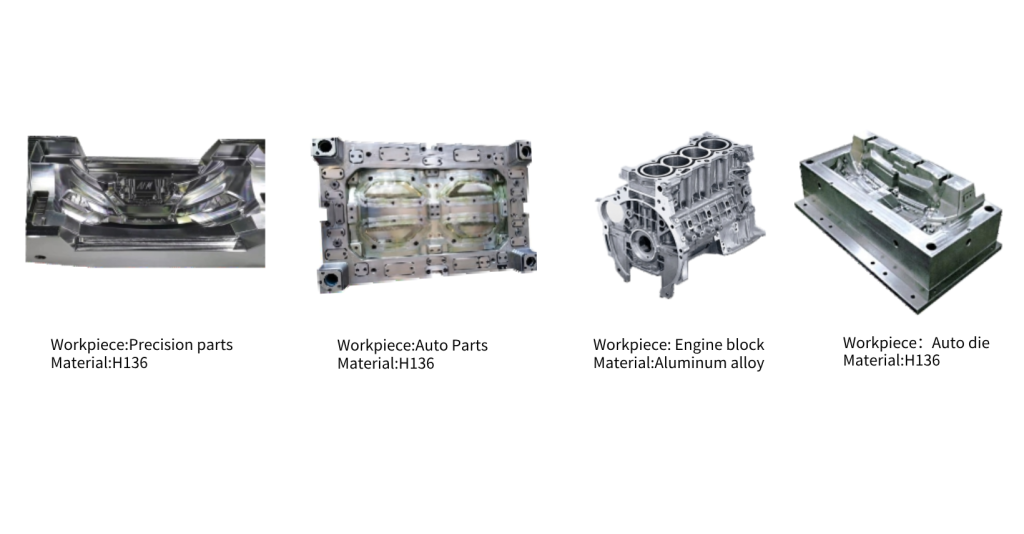

GMU2518 Universal Machining Center Application

The precision and high efficiency machining of large complex die parts is realized.

Technical Specifications

| GMU-2518 Item | Unit | Parameter | |

| System | Heidenhain iTNC640 | ||

| Travel | X/Y/Z axis travel | mm | 2500/1800/800 |

| A/C axis travel | degree | 0.48 | |

| Distance from worktable to spindle nose | mm | 500-1300 | |

| Worktable size/max payload | Mm/kg | 2500×1800/8000 | |

| Column door width | mm | 2700 | |

| T-groove size | pc/mm | 6pcs/28mmwidth | |

| ACswinghead | A-axis drive static torque | N.m | 1600 |

| C-axis drive static torque | N.m | 2000 | |

| A-axis brake torque | N.m | 1200 | |

| C-axis brake torque | N.m | 2000 | |

| Spindle | Maximum spindle speed/taper shank | rpm | 24000/HSK-A63 |

| Power(S1/S6-40%) | KW | 29/38 | |

| Torque(S1/S6-40%) | N.m | 69.4/86.8 | |

| Feedsystem | X/Y/Z axis rapid feed | m/min | 20/20/20 |

| Cutting feed speed | m/min | 10 | |

| A/C axis rapid feed | rpm | 20/20 | |

| Positioning precision ISO10791-4:1998 | X/Y/Z | mm | 0.015/0.015/0.008 |

| A/C | ARCSEC | 12/12 | |

| Repetitive positioning precision ISO10791-4:1998 | X/Y/Z | mm | 0.007/0.007/0.005 |

| A/C | ARCSEC | 6/6 | |

| Automatic tool change system (Bamoo Hat) |

Tool number | pcs | 26T |

| tool change time(tool-tool) | sec | 8 | |

| Tool max.length | mm | 300 | |

| Tool max.diameter/adjacent no tool | mm | Φ75/Φ120 | |

| Tool max.weight | kg | 8 | |

| Machine dimensions | Height | mm | 5600(Raise the ram to the highest position) |

| Length×Width | mm | 7950 x 5360 | |

| Net weight | T | 45 | |

| Power demand | kw | 80 | |